Powermax ultrasonic water meter is designed to survive against harsh environments, solids in water, magnetic vandalization, and other issues standard water meters cannot withstand. Primarily for residential use, its applications include revenue metering, AMR, and residential submetering with leakage detection. Utilizing a smart water meter is crucial for efficient water flow, saving on bills, and prompt leak repairs. Early leak detection can prevent property damage, making real-time leak alarms vital for managers and homeowners. Water filtration systems are equally important for treated water, but they can disrupt flow unintentionally.

Support Modbus wired, 4G, Pulse Output, RS485 Communication. Compatible with GB/T 26831, CJ/T 188, and Modbus RTU communication protocols.

Comply with GB/T 26831, CJ/T 188, and Modbus RTU communication protocol.

Now, let’s explore some primary features of Powermax:

Feature

• No moving mechanical parts and blockages. Wear-free ultrasonic technology.

• Temperature compensation for the whole temperature range from 0.1℃ to 50℃.

• Lead-free, comply with NSF / ANSI 61, Annex G.

• Patented sensor design. provides a precise signal, robust performance, and is not impacted by water impurity.

• Excellent long-term stability with consistent performance. Accuracy does not degrade over time.

• Tamper-proof design. Records when tampering is detected.

• Support up to 15 kinds of alarm: reverse, empty pipe, water leakage, pipe burst, low power, abnormal temperature, abnormal pressure, abnormal valve, PCB fault alarm, etc.

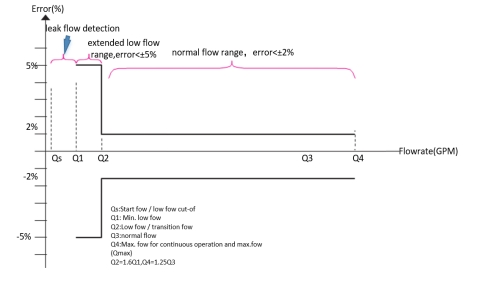

• Wide dynamic range, low starting flow rate.

• Unique straight-through sensor design offers no obstruction at all and very low-pressure drop.

• Large LCD, 9-digit display.

• More than 10 years of battery life.

• Fully sealed and waterproof design.

• Data Logger with 250 hours report 750 daily report and 24 monthly report.

• It suits new installations and retrofits. Support NB-IOT, Modbus LoraWan,4G, pulse output, RS485 communication, GPRS, and other data transmission methods.

•Compatible with GB/T 26831, CJ/T 188, and Modbus RTU communication protocols.

Technical Specifications:

| indicators | Technical parameters |

| DN(mm) | DN50~DN300 |

| Pressure Loss | Δp10 |

| Metrological Class | 2 |

| Pressure | PN16 PN25 |

| Environmental Temp | -25℃~+55℃,≤100%RH |

| Temperature Class | T30(default),T50 |

| The sensitivity level of the flow field | U5D3 |

| Sonic sound pass | 2,4 |

| Electromagnetic Class | E2 |

| Display | LCD 9 digits + prompt |

| Display content | flow(m³/h),flow total(m³),alarm code |

| Display range | Flow total:0m³~+9999999.99m³ |

| Power Consumption | <0.76mW |

| Enclosure Protection | IP68 |

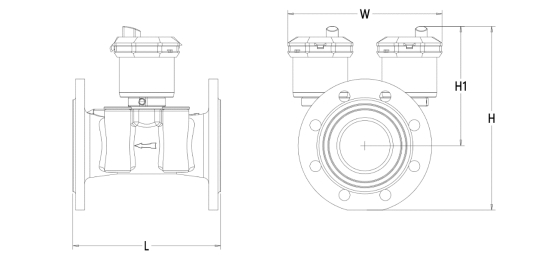

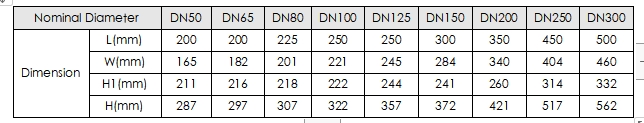

Appearance of size:

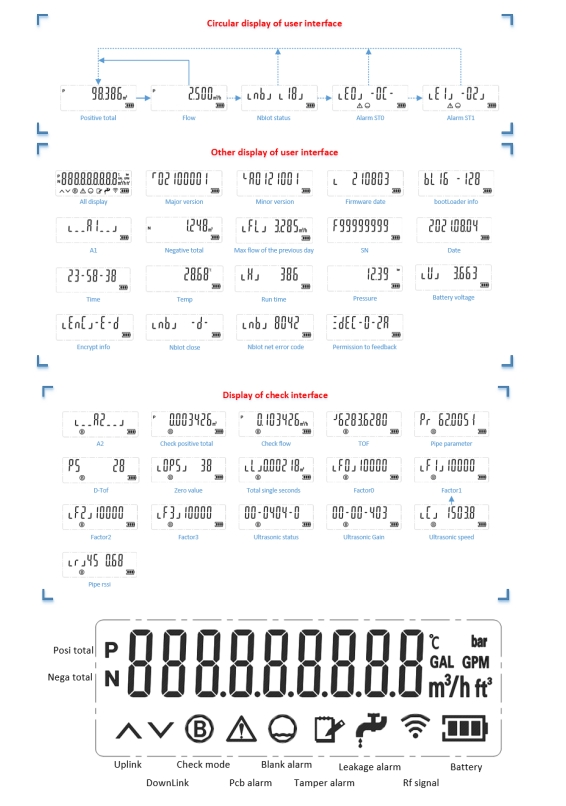

SF86-HB series Ultrasonic Water Meter has two main display interfaces:

1.User Interface:

2.Check Interface:

Their respective display contents and switch mode between interfaces are shown as follows:

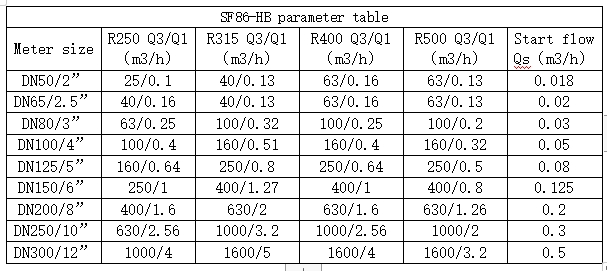

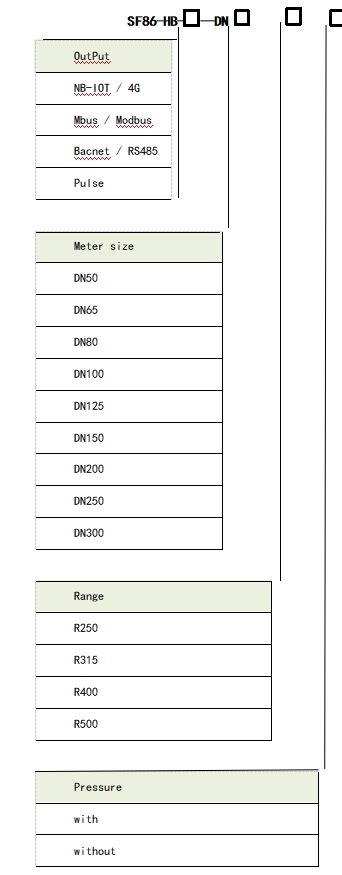

Product specification:

Notices for Installation

1. Flush pipes before installation to avoid gravel and other foreign objects;

2. Install a valve and filter before the water meter;

3. Do not touch the electrical part or pull wires to avoid damage during installation;

4. Reserve an adequate space for maintenance during installation;

5. When the water meter is installed in a horizontal or inclined way, the ultrasonic flow probe on pipes shall be placed horizontally, and when installed vertically, make sure the water flows from down to up.

6. Please note that the arrow direction on the pipe shall be consistent with the water flow direction during installation;

7. The joint washer shall be installed correctly to avoid misaligned washer blocking water and affecting the accuracy of the water meter;

8. The water meter shall not be installed at a place that may be affected by strong mechanical vibrations;

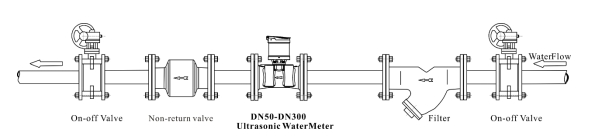

9. Installation Figure:

Special Notices:

- Be sure to install an on-off valve and filter before the water meter and another on-off valve is recommended after it for maintenance;

- If the ultrasonic water meter is installed through the flange, make sure the parallelism between the water meter flange and the pipe flange is not more than 0.5% of flange outer diameter and is less than 2mm, otherwise, it may result in damage to the the water meter.

10.Ensure a 5 times and a 3 times of straight-pipe run before and after the water meter, respectively, during installation;

11.The water meter shall refresh the display at every 8 seconds, and read the water meter (including the starting value and end value) 8 seconds at least after the valve is closed when test the water meter, otherwise the testing results may be affected;

12.Please make sure the medium flow is within the flow range of the water meter during test and use, otherwise it may result in damage to the water meter;

13.In case of any malfunction (e.g. metering failed, etc.) during use, please contact the related management department immediately and do not repair it by yourself;

14.The product is designed with a disposable anti-disassembly seal which shall be removed only by appointed personnel, or otherwise it shall be excluded from the free after-sales service.